Testing Methodology

Tensile Strength

Samples are subjected to controlled tension forces. Measurements record elongation percentages and failure points. Data indicates material flexibility limits.

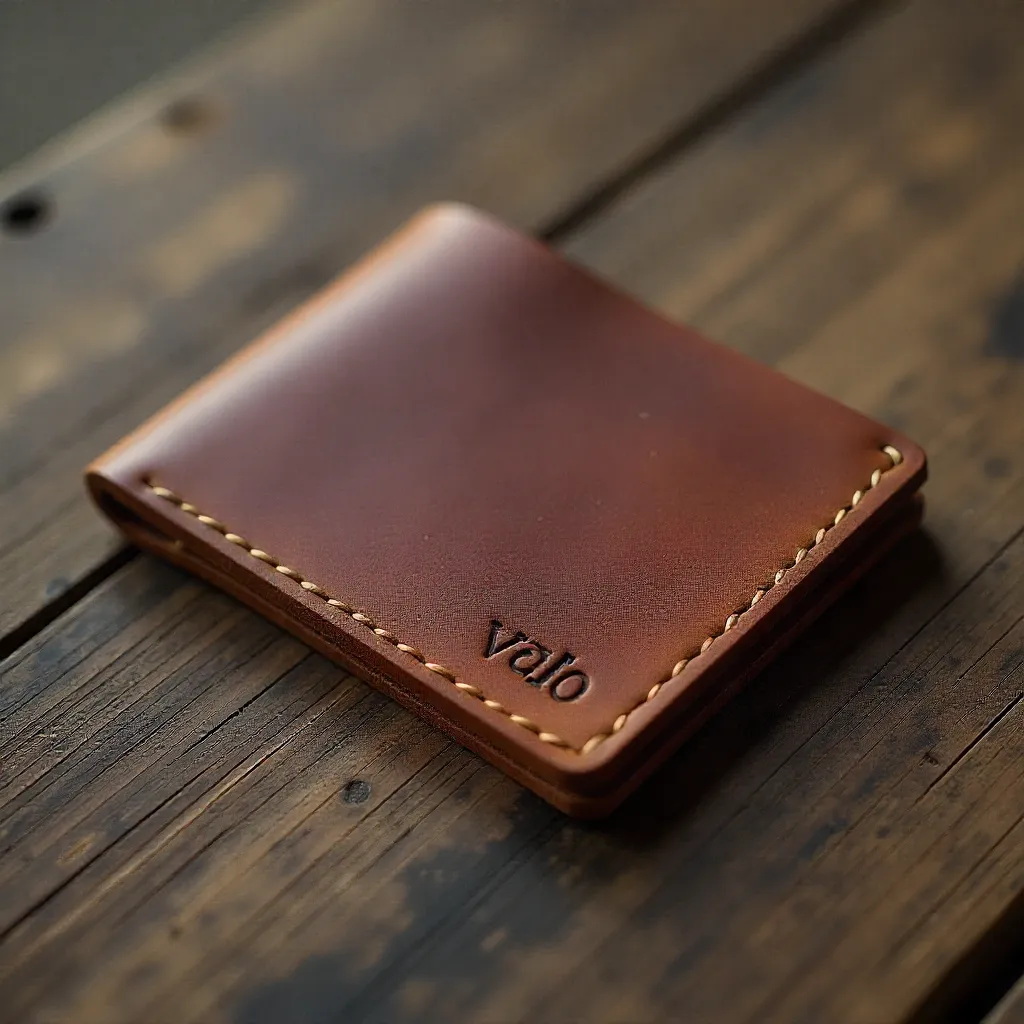

Abrasion Resistance

Surface wear is measured through standardized friction cycles. Visual documentation tracks texture changes and color shifts over extended periods.

Resilience Data Sheet

Year One

Initial patina development begins. Surface texture softens through regular contact. Color saturation increases by approximately 15-20%. Structural integrity remains unchanged.

Year Five

Patina patterns become more pronounced. Natural oils from handling create protective layers. Edge wear is minimal due to burnishing treatment. Stitching remains secure.

Year Ten

Material character fully developed. Surface shows consistent aging patterns. Structural components maintain functionality. Natural variations create unique visual identity.

Aging Simulation

Accelerated Conditions

Environmental chambers simulate extended use periods. Temperature, humidity, and UV exposure are controlled to predict long-term material behavior.

Natural Comparison

Field samples from extended use provide real-world validation. Comparison with laboratory data confirms simulation accuracy and material predictability.

Structural Integrity

Stitch Durability

Thread tension and stitch spacing are tested under load conditions. Failure modes are documented to inform design improvements.

Edge Stability

Burnished edges resist delamination and fraying. Edge treatment methods are evaluated for long-term performance characteristics.

Hardware Reliability

Fastener components undergo cycle testing. Mechanical wear patterns indicate expected service life and maintenance requirements.