Material Philosophy

Natural Evolution

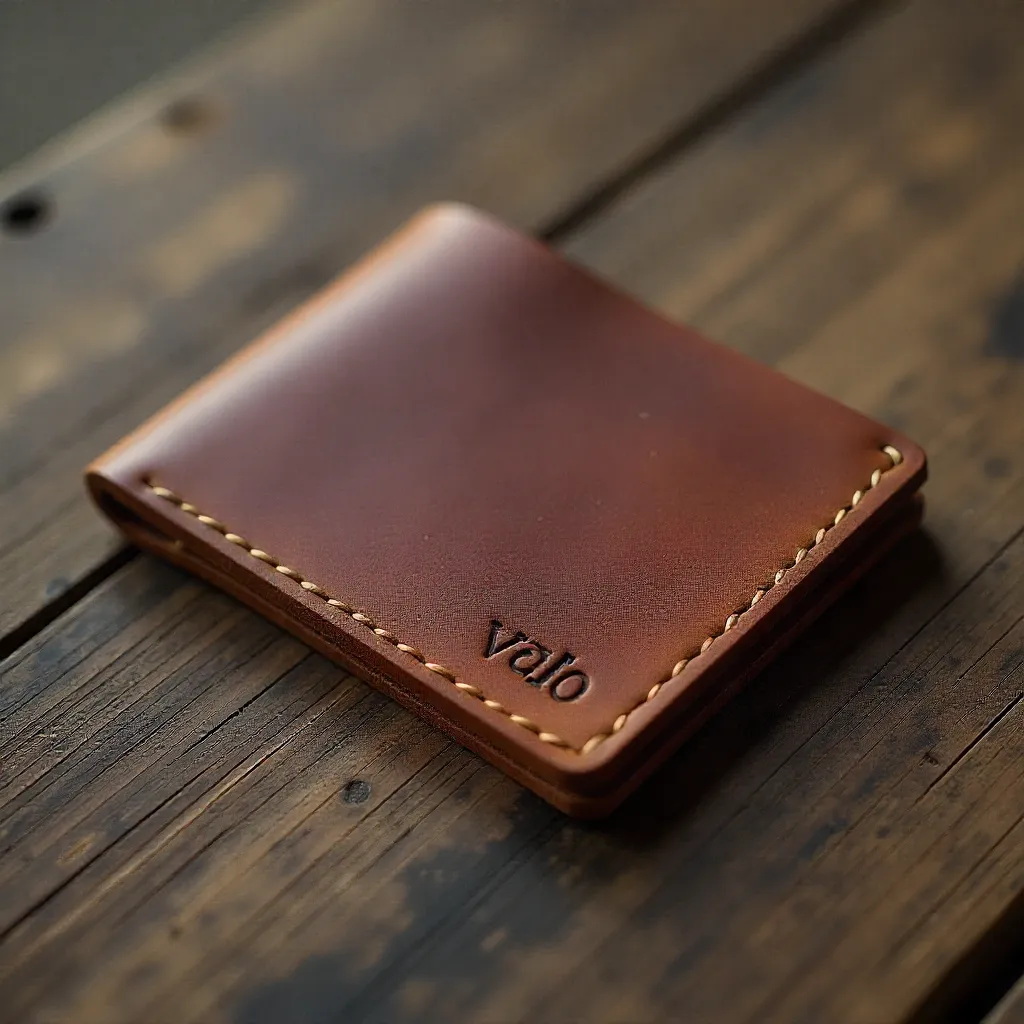

Leather transforms over time. The patina process creates unique markings that reflect individual usage patterns. Each surface tells a story of interaction and adaptation.

Structural Integrity

Traditional techniques ensure longevity. Saddle stitching and burnished edges provide strength that modern methods cannot replicate. Every connection point is reinforced.

Surface Character

Full-grain vegetable-tanned hides preserve natural markings. Scars, grain variations, and texture differences become design elements rather than flaws.

Process Overview

Selection

Each hide is examined for grain consistency and structural soundness. Only materials meeting specific criteria proceed to production stages.

Cutting

Precision cutting maximizes material efficiency while respecting natural grain direction. Patterns are aligned to optimize strength characteristics.

Assembly

Hand-stitched connections create permanent bonds. Thread tension and stitch spacing are calibrated for optimal load distribution.

Finishing

Edge burnishing and surface treatment protect against environmental factors. Final inspection ensures dimensional accuracy and aesthetic consistency.

Technical Specifications

Thread Specifications

Waxed linen thread provides superior resistance to abrasion and environmental exposure. Stitch density is calculated based on load requirements.

Hardware Components

Solid brass fasteners resist corrosion and maintain functionality under repeated use. Each component is tested for mechanical reliability.

Usage Patterns

Daily Carry

Items designed for regular interaction develop surface patina through contact with hands, pockets, and environmental elements. Color shifts occur gradually.

Storage Considerations

Proper storage conditions maintain material integrity. Avoid excessive moisture, direct sunlight, and extreme temperature fluctuations.

Maintenance

Minimal maintenance preserves natural characteristics. Occasional conditioning supports material flexibility without altering surface appearance.

Production Standards

Quality Control

Every completed item undergoes dimensional verification and structural testing. Defects are identified and addressed before final approval.

Documentation

Production records track material sources, processing methods, and completion dates. This information supports traceability and quality assurance.